This comprehensive report explores the superior durability and performance of Inborn's rotational molded emergency shelters. As a leading rotational mold manufacturer, Inborn leverages cutting-edge molding technology to create rugged, long-lasting shelters that outperform traditional tents and modular panel systems. The shelters feature seamless construction, UV and weather resistance, and remarkable impact durability, making them ideal for rapid deployment in disaster zones and harsh environments. Field deployments have confirmed their longevity, low maintenance, and ease of repair, while their design incorporates sustainable materials and processes. Comparative analysis highlights that Inborn's shelters last significantly longer and require less upkeep than conventional alternatives. Integrated innovations, such as solar mounts and modularity, further enhance their utility and habitability. With a focus on both emergency shelter durability and environmental responsibility, Inborn continues to set new industry standards, ensuring safety, comfort, and resilience for vulnerable populations worldwide.

As communities around the world face increasingly frequent natural disasters and humanitarian crises, the need for robust, reliable, and quickly deployable emergency shelters has never been greater. Inborn, a globally recognized rotational mold manufacturer, has positioned itself at the forefront of this urgent demand by delivering innovative rotational molded emergency shelters. This report delves deep into the durability, performance, and real-world advantages these shelters provide, and how they stand apart in a rapidly evolving sector.

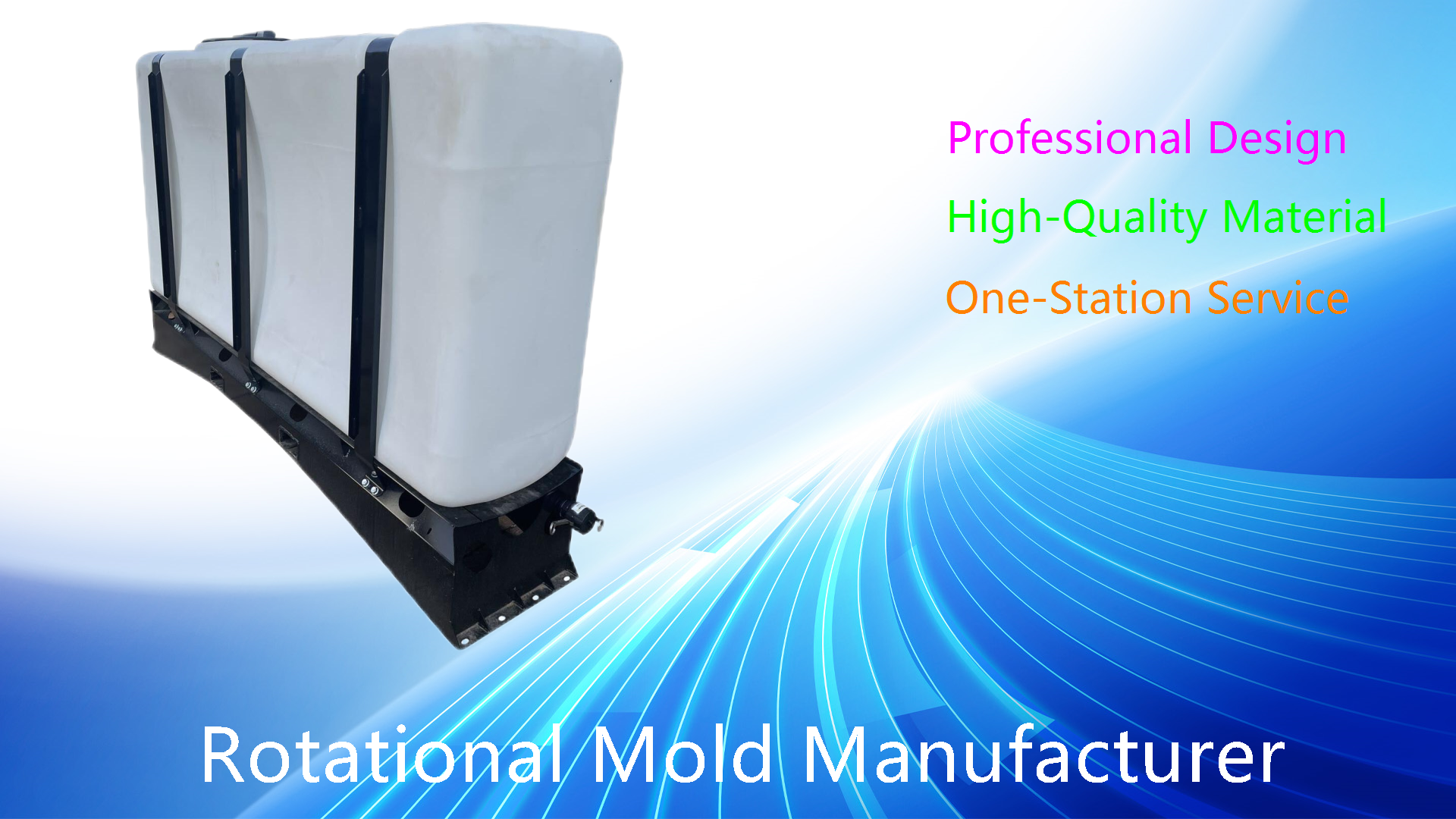

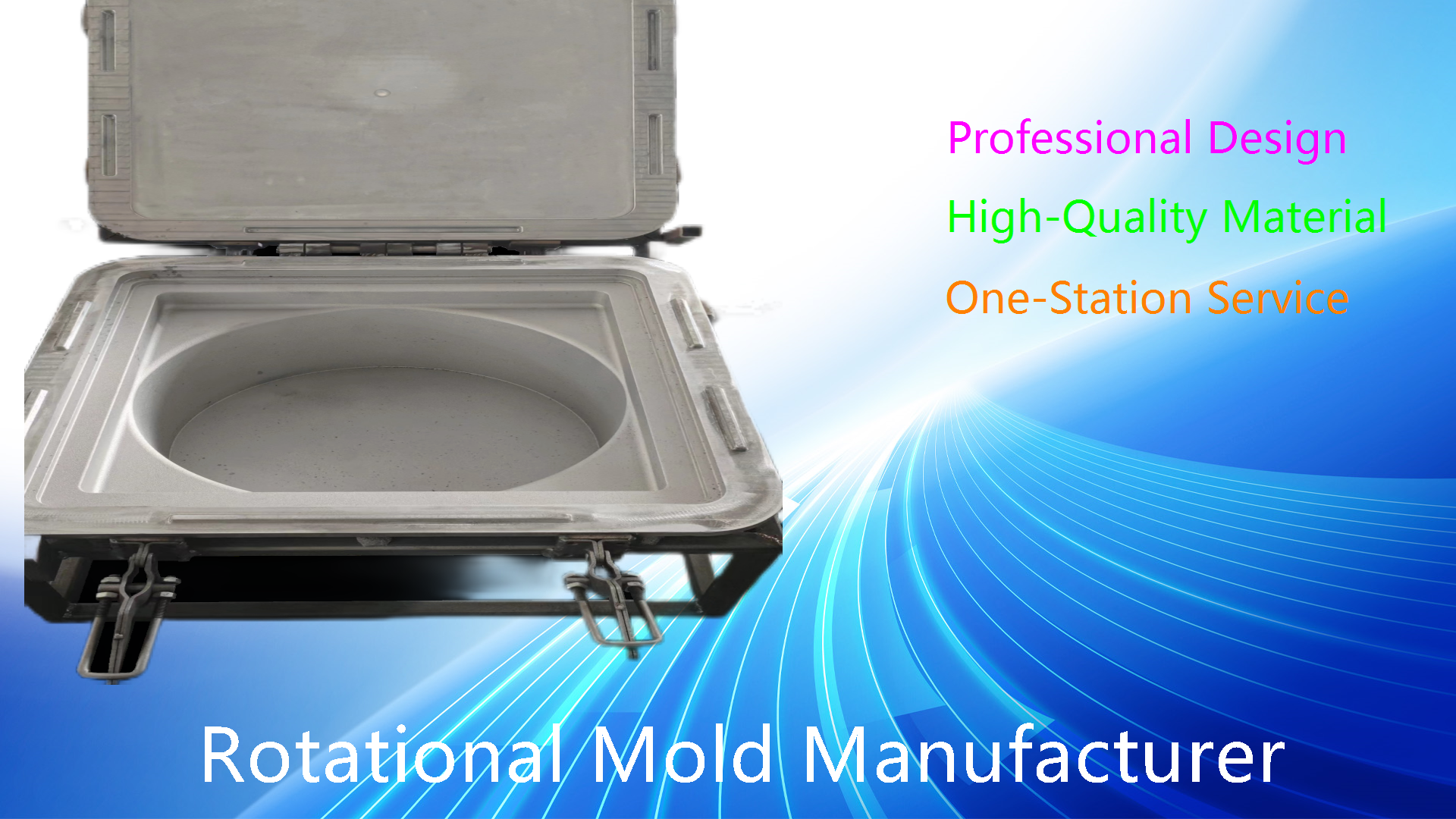

Rotational molding is a manufacturing process that utilizes high temperatures and rotational motion to produce seamless and hollow plastic products. For Inborn, this technology forms the backbone of their emergency shelter solutions, enabling the creation of robust, uniform, and versatile structures. The process allows for design flexibility, enhanced structural integrity, and the use of UV-resistant, weatherproof polymers—key attributes for emergency applications.

Seamless Construction: Eliminates weak points and joints for improved strength and water-resistance

UV & Weather Resistance: Special polymers safeguard occupants from extreme sun, rain, and wind

Impact Resistance: Designed to withstand debris impact and rough handling during deployment

Thermal Insulation: Multi-layered walls reduce heat transfer, providing comfort across climates

Portability: Lightweight for logistics efficiency, stackable, and easy to assemble

Durability is the single most critical metric for any emergency shelter. Shelters must survive harsh transportation, rapid deployment, and continue to maintain structural integrity in hostile environments. Inborn's rotational molded shelters are engineered with these realities in mind. Rigorous laboratory testing and feedback from field deployments have consistently demonstrated their exceptional longevity and resilience.

undefined

Structural Load Tests: Inborn's shelters are subjected to static and dynamic load testing, simulating the weight of snow accumulation, high winds, and occupant movement. These shelters consistently outperform traditional fabric tents and modular panel systems, thanks to their monolithic rotomolded shells.

Impact and Puncture Resistance: In environments with flying debris or during hasty assembly, traditional shelters are prone to tears and punctures. Rotational molded shelters from Inborn withstand significant impact forces with minimal cosmetic damage, preserving occupant safety and utility.

From the arid deserts to the frozen tundra, emergency shelters must perform under a wide temperature spectrum and resist degradation from UV exposure, rain, and wind. Inborn embeds UV stabilizers directly into the polyethylene matrix during manufacturing, resulting in shelters that maintain their color, flexibility, and mechanical properties for years even in direct sunlight.

UV Resistance: Tested for decades-worth of sun exposure with minimal fading or brittleness

Waterproof Design: Integrated floors, seamless walls, and gasketed entryways prevent leaks and flooding

Wind Resistance: Aerodynamic profiles and anchor points allow shelters to resist uplift and overturning

Inborn’s rotational molded emergency shelters have been deployed in diverse crisis zones, including hurricane-hit Caribbean islands, remote refugee encampments in Africa, and earthquake-stricken communities in Asia. Feedback from these challenging deployments has shaped iterative improvements in design and material selection. Shelters routinely outlast fabric tents by several years, maintaining habitability and security even under repeated relocation and assembly cycles.

Case studies from international NGOs highlight reduced maintenance costs and fewer replacements, underscoring the value proposition of rotational molded solutions. In many regions, Inborn’s shelters have transitioned from temporary emergency use to semi-permanent dwellings, thanks to their superior durability and comfort.

Rotational molded shelters require minimal maintenance. Their non-porous surfaces are easy to clean and disinfect, and modular repair kits allow damaged sections to be patched or replaced on-site. This ease of care is crucial in disaster zones where resources are limited, and rapid turnover of shelter stockpiles is not feasible.

Easy to clean with common disinfectants

Can be redeployed multiple times with minimal wear

Repairable with simple hand tools and patch kits

| Criteria | Rotational Molded (Inborn) | Traditional Tents | Modular Panel Systems |

|---|---|---|---|

| Durability | 10+ years | 1-2 years | 5-7 years |

| Maintenance | Low | High | Moderate |

| Water Resistance | Excellent | Poor-Moderate | Good |

| Thermal Insulation | Good | Poor | Good |

| Portability | Excellent | Excellent | Moderate |

This comparative table demonstrates the significant advantages Inborn’s rotational molded emergency shelters have over traditional options, particularly for extended or repeat deployments.

With increased attention on sustainable manufacturing, Inborn uses recyclable polymers and energy-efficient molding processes. At end-of-life, shelters can be ground and reprocessed into new products, minimizing landfill waste. The long service life of rotational molded shelters also reduces the consumption of resources over time.

Continuous research and development at Inborn’s facilities have led to a new generation of shelters featuring integrated solar mounts, advanced ventilation, and modular connectivity for rapid expansion into larger compounds. These innovations not only improve user comfort but also maximize the utility of rotational molding as a versatile and reliable manufacturing technology.

As a premier rotational mold manufacturer, Inborn not only sets industry benchmarks in quality but also collaborates with humanitarian agencies to ensure that emergency shelter durability meets the highest standards. By leveraging decades of expertise and progressive design philosophies, Inborn’s solutions exemplify how advanced molding technology directly translates into improved disaster resilience and human welfare.

Looking to the future, Inborn is expanding its partnerships with relief organizations and governments to integrate smart monitoring systems, further enhancing both the safety and longevity of its shelters. These steps reinforce Inborn’s commitment to innovation and its reputation as a leading rotational mold manufacturer in the humanitarian sector.

In summary, durability is the defining attribute of Inborn's rotational molded emergency shelters. Through careful material selection, precision engineering, and a culture of continuous improvement, Inborn has redefined expectations for emergency housing. These resilient shelters are proven in the field, cost-effective over their lifecycle, and adaptable to the unpredictable demands of disaster response. As communities and agencies worldwide seek more permanent, sustainable, and dependable shelter solutions, Inborn’s rotational molded offerings are poised to lead the way—delivering on the promise of safety, protection, and dignity for those in need.

Tags:Rotational mould factory,Aluminum Rotational Mold,Rotational Molded Products,Rotational Products