Rotational molding has established itself as the premier method for producing rigid plastic containers thanks to its unique combination of design flexibility, cost-effectiveness, and superior product integrity. Inborn, a top-tier rotational mold manufacturer, leverages advanced technology, strict quality control, and customer-centric service to deliver customized, seamless, and durable plastic containers for a variety of industries. The process offers significant advantages such as uniform wall thickness, leak-proof construction, and the ability to incorporate complex features directly into the product. By also offering solutions as a plastic pallet manufacturer, Inborn extends its expertise across storage and logistics sectors. Committed to innovation and sustainability, Inborn remains at the forefront of industry trends, providing high-quality, eco-friendly, and tailored solutions that meet the evolving needs of its clients. For companies seeking reliable partners for rigid plastic container production, Inborn and rotational molding represent the best possible choice.

With an ever-growing demand for durable, lightweight, and cost-efficient rigid plastic containers, manufacturers are continuously searching for advanced technologies to enhance their products. Rotational molding has emerged as a leading solution, providing manufacturers and end-users with a host of unique benefits—ranging from design flexibility to superior mechanical properties. As a premier rotational mold manufacturer, Inborn stands at the forefront of this industry, harnessing the latest innovations to deliver world-class solutions for rigid plastics.

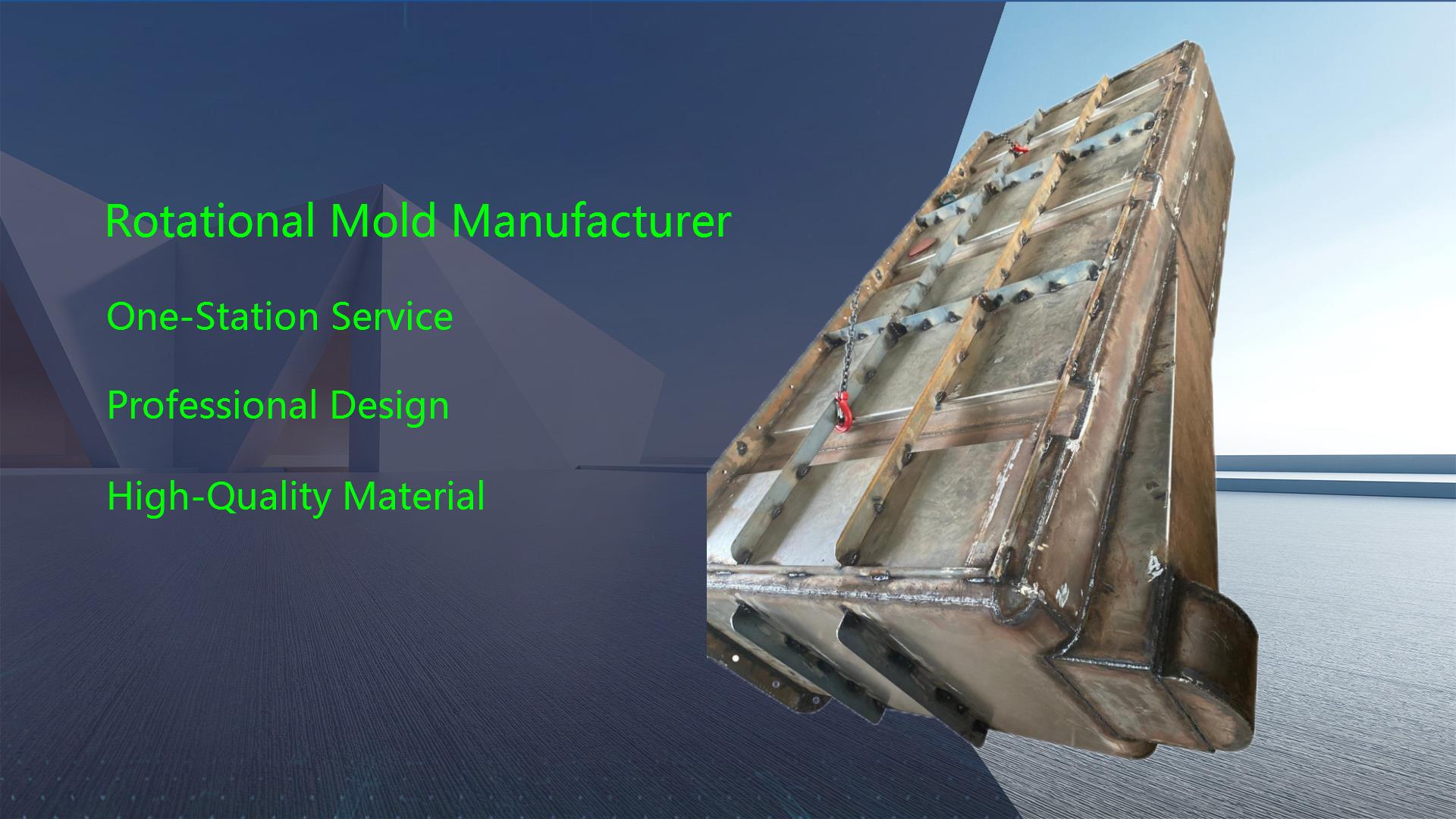

Rotational molding, often called "rotomolding," is a manufacturing process used to create hollow plastic products. This technique involves placing powdered plastic material into a hollow mold, which is then heated and rotated along two perpendicular axes. The plastic melts, coats the inside of the mold evenly, and solidifies into a seamless, strong, and lightweight container once cooled. Rotational molding is especially favored for creating large, robust items—including tanks, bins, toys, and of course, rigid plastic containers.

Unlike injection or blow molding, rotational molding produces containers with uniform wall thickness, virtually no weld lines, and the ability to incorporate intricate design elements. These advantages make it a preferred choice for various industries, from food and beverage to chemicals and pharmaceuticals.

undefined

Inborn is recognized for its commitment to quality and innovation in the field of rotational molding. As a top rotational mold manufacturer, Inborn leverages cutting-edge design software, precision engineering, and high-grade materials to create molds that yield superior rigid plastic containers.

Precision Engineering: Inborn’s engineering team uses advanced CAD/CAM systems to ensure every mold is optimized for efficiency and accuracy.

Custom Solutions: Whether clients require unique dimensions, complex geometries, or specific aesthetic features, Inborn delivers customized solutions to meet diverse needs.

Quality Assurance: Rigorous quality control protocols ensure that every container produced meets or exceeds industry standards for durability and performance.

Inborn’s focus on continuous improvement and customer satisfaction has set new benchmarks in the rotational molding industry.

Rotational molding ensures the even distribution of plastic material during the manufacturing cycle. This results in containers with consistent wall thickness—minimizing weak points and enhancing structural integrity. Such containers resist impact, cracking, and environmental stress, making them ideal for both storage and transport applications.

For businesses seeking affordable solutions, rotational molding offers significant cost advantages. Mold tooling is less expensive compared to injection molding, and the process is highly efficient for producing medium to large volumes. This affordability extends to the production of large or complex containers, where alternative methods may become prohibitively expensive.

One of the standout features of rotational molding is its remarkable design flexibility. Manufacturers like Inborn can easily incorporate features such as threaded inserts, handles, curves, and internal baffles directly into the mold. This eliminates the need for additional assembly or post-processing, resulting in versatile, ready-to-use containers tailored to specific client requirements.

Thanks to the rotational molding process, containers are formed as a single, seamless piece. This construction eliminates joints and weld lines that can lead to leaks or contamination, ensuring that rigid plastic containers are suitable for even the most demanding applications—such as food storage, pharmaceuticals, and hazardous chemicals.

Rotational molding is inherently eco-friendly. The process produces minimal waste, allows for the use of recyclable and recycled plastic materials, and requires less energy compared to other molding techniques. Inborn prioritizes sustainable practices, selecting materials and processes that reduce environmental impact while maintaining superior product quality.

Food and Beverage Storage: Containers for liquid and dry goods, manufactured to meet strict hygiene standards.

Chemical Storage: High-density, chemical-resistant tanks and drums for safe containment and transportation.

Pharmaceuticals: Leak-proof, contaminant-free containers for sensitive medical and laboratory materials.

Industrial Applications: Heavy-duty bins, crates, and fuel tanks built for demanding environments.

Consumer Goods: Products such as coolers, storage boxes, and outdoor furniture.

Inborn’s expertise in rotational molding ensures that each product can be customized to the unique requirements of these diverse markets.

As a leading rotational mold manufacturer, Inborn is continually adopting new materials and technologies to drive innovation. From UV-stabilized and flame-retardant plastics to antimicrobial and conductive polymers, the company can tailor rigid plastic containers to meet specific performance criteria. Advanced techniques, such as multi-layer molding and in-mold graphics, add even more value for customers seeking highly functional and visually appealing products.

| Method | Advantages | Disadvantages |

|---|---|---|

| Rotational Molding | Design flexibility, uniform walls, cost-effective for large items, seamless construction | Longer cycle times, not ideal for extremely high-volume small parts |

| Injection Molding | Fast cycle times, high precision, good for small parts | High tooling costs, limited to certain shapes |

| Blow Molding | Suited for hollow containers, quick production | Less control over wall thickness, weld lines may be present |

This comparison demonstrates why rotational molding, particularly when performed by an expert like Inborn, remains the top choice for rigid plastic containers requiring unique shapes, large dimensions, and reliable performance.

Inborn adheres to the most stringent quality control measures throughout the manufacturing process. Every rigid plastic container undergoes testing for strength, leak resistance, and dimensional accuracy. Additionally, Inborn’s production facilities are certified to international standards such as ISO 9001, ensuring consistent quality and traceability for every batch.

What sets Inborn apart as a rotational mold manufacturer is its unwavering focus on customer satisfaction. From the initial design consultation to prototyping, production, and delivery, Inborn collaborates closely with clients to ensure every need is met. Responsive customer service, transparent communication, and reliable after-sales support have earned Inborn a reputation for excellence.

While Inborn is best renowned as a rotational mold manufacturer, it is also engaged in related fields such as plastic pallet manufacturer solutions. Plastic pallets share many of the same performance requirements as rigid containers—namely durability, lightweight, and resistance to chemicals and weather. By applying rotational molding technology, Inborn produces high-performance plastic pallets and containers that excel across logistics, storage, and transportation industries. The synergy between being a top rotational mold manufacturer and a plastic pallet manufacturer allows Inborn to serve a broader market with industry-leading solutions.

The future is bright for rotational molding in the rigid plastics sector. As global industries demand higher standards for safety, sustainability, and customization, manufacturers like Inborn are poised to lead the way. Continued research into advanced polymers, eco-friendly materials, and digital manufacturing processes will further expand the capabilities of rotomolded products. Inborn’s ongoing investment in R&D ensures that its clients always benefit from the latest advancements, whether they require rigid containers, tanks, or plastic pallets.

For businesses seeking reliable, cost-effective, and innovative rigid plastic containers, rotational molding stands out as the best solution. Inborn, as a leading rotational mold manufacturer, combines technical expertise, state-of-the-art facilities, and a customer-first philosophy to deliver products that exceed expectations. The company’s experience in both rigid containers and as a plastic pallet manufacturer further enhances its ability to serve complex industrial needs.

Whether you require custom storage tanks, transport containers, or specialty products, Inborn’s rotational molding solutions offer unmatched quality, versatility, and value. Partner with Inborn to experience the difference that true expertise and innovation can make.

Tags:Rotational Mold manufacturer,Rotational mould factory,Aluminum Rotational Mold,Rotational Molded Products