In the world of water storage solutions, the demand for durable, seamless, and cost-effective tanks is ever-growing. As industries and households alike seek reliable storage solutions, rotational molding has emerged as a leading manufacturing process. Among the pioneers in this field is Inborn, a renowned rotational mold manufacturer that has set the standard for quality and innovation in water tank production.

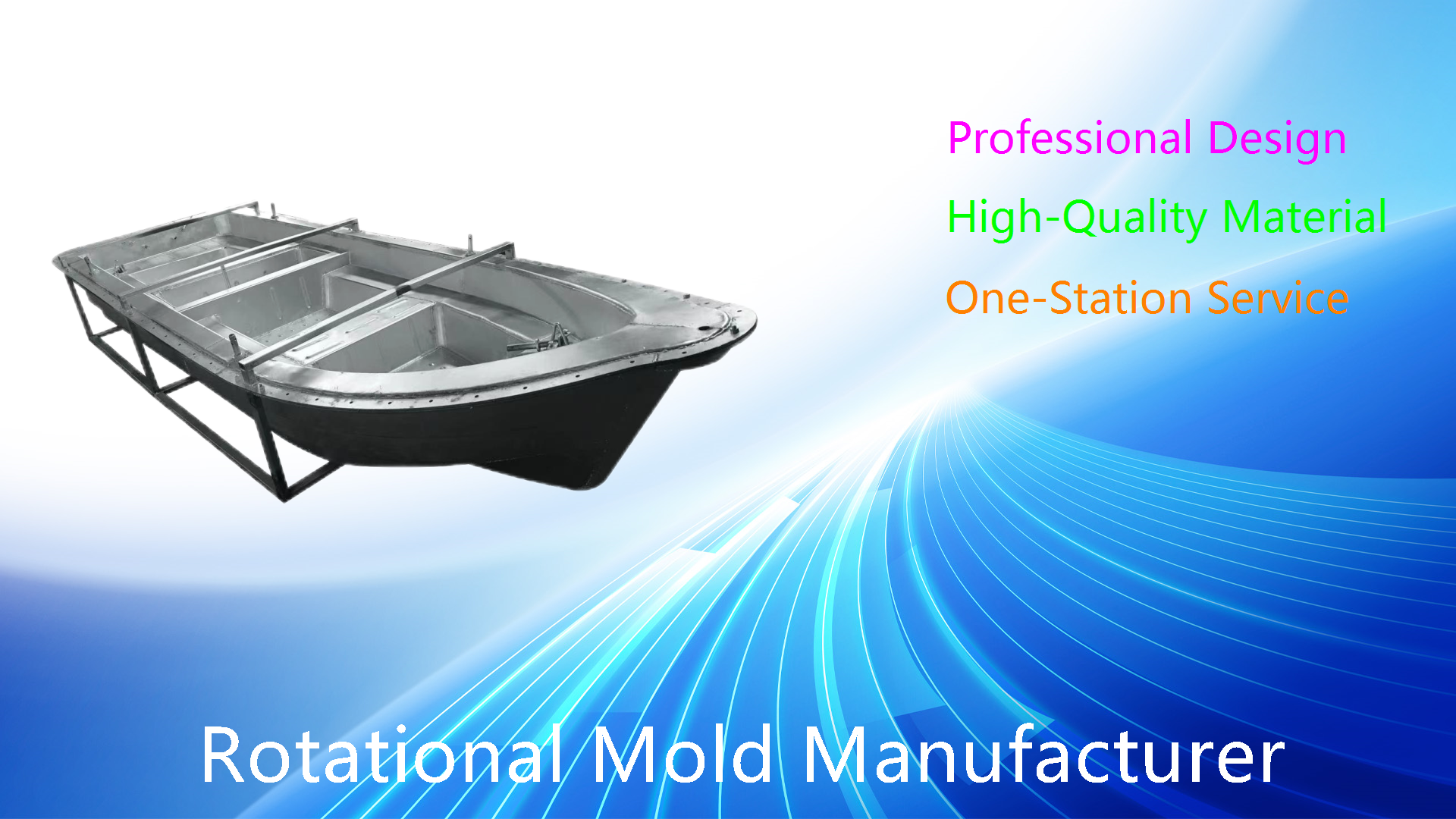

Rotational molding, often referred to as rotomolding, is a versatile plastic molding process used to create hollow, seamless products. This method involves heating a plastic material in a mold that is slowly rotated along two perpendicular axes. The centrifugal force ensures even distribution of the material, resulting in a uniform thickness and seamless finish.

The process is particularly advantageous for producing large, durable items such as water tanks. It allows for intricate designs and the integration of complex features without compromising the structural integrity of the product. Inborn has mastered this process, leveraging its capabilities to produce water tanks that are both functional and aesthetically pleasing.

One of the most significant advantages of rotational molding is its ability to produce seamless products. Water tanks manufactured using this method have no joints or seams, which are common points of failure in traditional tank designs. This seamless construction minimizes the risk of leaks, ensuring long-term reliability and peace of mind for users.

Rotomolded water tanks are renowned for their durability. The uniform wall thickness achieved through this process provides enhanced strength and resistance to impact. Inborn's tanks are designed to withstand harsh environmental conditions, making them ideal for both residential and industrial applications.

Rotational molding offers unparalleled design flexibility. Inborn utilizes this flexibility to create water tanks in a variety of shapes, sizes, and colors. Whether you need a compact tank for a small household or a large-capacity solution for industrial use, Inborn can tailor its products to meet your specific requirements.

The efficiency of the rotational molding process translates to cost savings for consumers. The ability to produce complex shapes without additional tooling costs makes rotomolded tanks more affordable than those made using other methods. Inborn's commitment to quality ensures that these savings do not come at the expense of durability or performance.

As a leader in the rotational molding industry, Inborn has built a reputation for excellence. With state-of-the-art facilities and a team of skilled professionals, the company is dedicated to producing water tanks that meet the highest standards of quality and performance.

Inborn's engineering team is at the forefront of innovation. By continually exploring new materials and techniques, they are able to enhance the performance and longevity of their products. This commitment to innovation ensures that Inborn's water tanks are always ahead of the curve.

Quality is a cornerstone of Inborn's manufacturing process. Each water tank undergoes rigorous testing to ensure it meets the company's high standards. From material selection to final inspection, Inborn's quality assurance protocols guarantee that every tank is built to last.

Inborn's success is built on a foundation of customer satisfaction. The company works closely with clients to understand their needs and provide tailored solutions. This customer-centric approach has earned Inborn a loyal client base and a reputation as a trusted partner in the water storage industry.

Rotomolded water tanks are versatile and can be used in a wide range of applications. Here are some of the key areas where Inborn's tanks excel:

Residential Use: Ideal for rainwater harvesting and domestic water storage, providing a reliable and eco-friendly solution for households.

Agricultural Use: Essential for irrigation and livestock watering, helping farmers manage water resources efficiently.

Industrial Use: Suitable for storing chemicals and other industrial liquids, ensuring safety and compliance with industry standards.

Commercial Use: Perfect for businesses that require large volumes of water storage, such as car washes and laundromats.

In an era where sustainability is paramount, rotational molding offers an environmentally friendly manufacturing option. The process generates minimal waste, and the materials used are often recyclable. Inborn is committed to sustainability, implementing eco-friendly practices throughout its operations to minimize its environmental footprint.

Moreover, the durability and longevity of rotomolded water tanks mean fewer replacements and less waste over time. This aligns with global efforts to reduce plastic waste and promote sustainable consumption.

Rotational molding is revolutionizing the water tank industry, offering a seamless, durable, and cost-effective solution for a wide range of applications. Inborn, as a leading rotational mold manufacturer, continues to set the benchmark for quality and innovation. By choosing Inborn's rotomolded water tanks, consumers can enjoy the benefits of superior design, exceptional durability, and environmental responsibility.

As the demand for reliable water storage solutions grows, Inborn remains committed to meeting the needs of its customers with products that stand the test of time. Whether for residential, agricultural, industrial, or commercial use, Inborn's rotomolded water tanks are the go-to choice for those seeking excellence in water storage.

In conclusion, the future of water storage is seamless, durable, and sustainable, thanks to the advances in rotational molding technology and the expertise of companies like Inborn. With a focus on quality, innovation, and customer satisfaction, Inborn is poised to lead the industry into a new era of water storage solutions.