Inborn, a leading rotational mould manufacturer, has revolutionized the agricultural water tank market with its state-of-the-art design and manufacturing processes. These tanks are designed to meet the demanding needs of the agricultural sector, providing durability, efficiency, and cost-effectiveness.

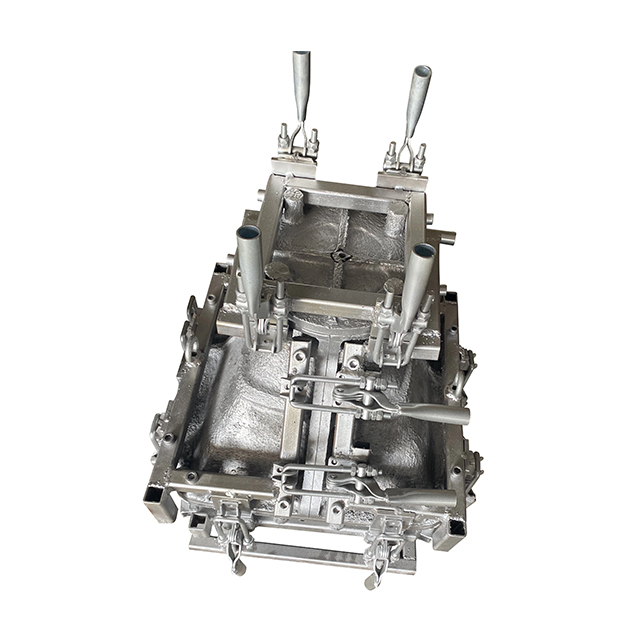

Rotational molding, or rotomolding, is a highly efficient process used in the manufacturing of Inborn's agricultural water tanks. This method involves loading a mold with plastic resin and rotating it along two perpendicular axes. The heat melts the resin, which coats the interior of the mold to form a uniform, seamless tank. This technique ensures even wall thickness and superior strength compared to other methods.

Uniform Wall Thickness: Ensures strength and durability.

Seamless Construction: Eliminates potential weak points, reducing the risk of leaks.

Flexibility in Design: Allows for complex shapes and sizes to meet diverse agricultural needs.

Inborn utilizes high-quality, UV-stabilized polyethylene in the production of its agricultural water tanks. This material is chosen for its robustness, resistance to harsh environmental conditions, and longevity. The UV stabilization prevents degradation from sunlight, ensuring the tanks remain functional and reliable over time.

Rigorous Testing: Each tank undergoes stringent quality control tests, including pressure and leak tests, to ensure it meets the highest standards.

Certifications: Inborn's manufacturing processes are certified to international standards, reflecting our commitment to quality and safety.

R&D and Innovation: Continuous research and development efforts enable Inborn to integrate the latest technological advancements into our products.

Inborn offers extensive customization options to cater to the specific needs of different agricultural operations. Whether you need a tank with specific dimensions or additional features such as integrated outlets and inlets, our R&D and design teams are equipped to deliver.

As a leading OEM/ODM supplier, Inborn provides tailored solutions for businesses requiring private labeling or custom-designed water tanks. Our ability to deliver bespoke products with quick turnaround times sets us apart in the industry.

Inborn's rotational molding process is not only efficient but also cost-effective. This efficiency translates into competitive pricing for our customers, providing excellent cost performance without compromising on quality.

The durability and longevity of our tanks result in lower maintenance and replacement costs over time, offering significant long-term savings for agricultural operations.

Inborn has established a robust distribution network, partnering with wholesalers, agents, and distributors worldwide. This ensures our agricultural water tanks are readily available to customers across different regions.

Our strategically located factory in China ensures a reliable and uninterrupted supply of products, meeting the demands of our global customer base. With a focus on efficiency and reliability, Inborn is committed to delivering top-quality tanks on time, every time.

Inborn's rotational mold agricultural water tanks exemplify the perfect blend of advanced manufacturing techniques, superior materials, and innovative design. With a focus on quality, customization, and cost-effectiveness, we continue to set the standard in the agricultural water tank industry. Whether you are looking for a reliable supplier or seeking OEM/ODM services, Inborn is your trusted partner in achieving exceptional results.

For more information or to request a quote, contact Inborn today and experience the difference that our cutting-edge rotational molding technology can make for your agricultural needs.