In today's market, the demand for durable and aesthetically pleasing kiosks is on the rise, whether for retail, information dissemination, or public use. The manufacturing process behind these kiosks plays a critical role in their longevity and functionality. Rotational molding, or rotomolding, has emerged as an ideal method for producing durable kiosks. Inborn, a leader in rotational mold manufacturing, leverages this technique to create kiosks that are not only robust but also versatile in design and application.

Rotational molding offers significant advantages in the production of durable kiosks. The process involves heating polymer resin inside a rotating mold, allowing the material to evenly coat the interior surfaces. This method produces kiosks with uniform wall thickness, seamless construction, and enhanced material properties, all of which contribute to their durability. Inborn utilizes these benefits to manufacture kiosks that can withstand harsh environmental conditions and heavy usage without compromising on appearance or functionality.

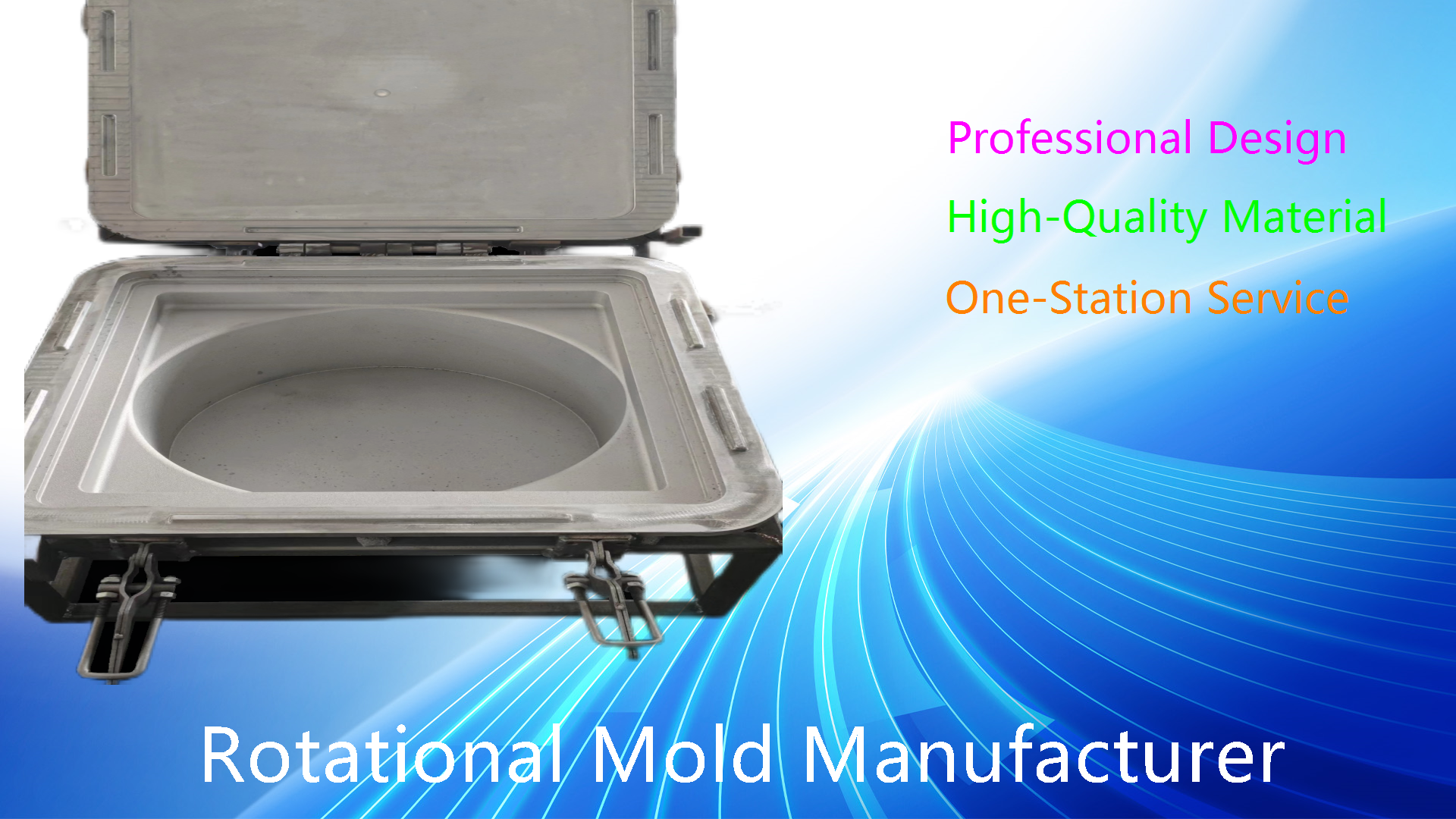

Inborn’s expertise in rotational molding allows us to produce kiosks that are durable, reliable, and customized to meet the specific needs of our clients. Here are the key technical advantages that make our rotational molded kiosks stand out:

Seamless and Sturdy Construction: One of the primary benefits of rotomolding is the ability to create kiosks with a seamless design. This construction eliminates weak points, making the kiosks more resistant to impacts, weather, and other external stresses. The seamless nature also enhances the aesthetic appeal of the kiosks, giving them a sleek, modern look.

Uniform Wall Thickness: Rotational molding ensures that the kiosks have consistent wall thickness throughout, which is crucial for their structural integrity. This uniformity enhances the kiosks' ability to withstand the rigors of daily use, making them ideal for both indoor and outdoor environments.

Material Versatility: The rotational molding process allows for the use of a variety of polymers, including UV-resistant and weatherproof materials. Inborn selects the most appropriate materials for each kiosk, ensuring they are resistant to fading, cracking, and other forms of degradation, even in extreme climates.

Customization and Flexibility: Rotomolding offers unparalleled flexibility in design, enabling the creation of kiosks in a wide range of shapes, sizes, and configurations. Whether you need a simple, functional kiosk or a more complex, customized design, Inborn’s rotational molding process can accommodate your specific requirements.

Kiosks produced through rotational molding offer several advantages over those made with traditional manufacturing methods. The seamless construction and uniform wall thickness provide superior durability, reducing maintenance needs and extending the lifespan of the kiosks. The material versatility ensures that the kiosks can endure challenging environments, maintaining their structural integrity and appearance over time. Additionally, the customization options available with rotomolding allow for greater design innovation, enabling the creation of kiosks that meet specific functional and aesthetic requirements.

At Inborn, we are dedicated to producing high-quality kiosks using the advanced rotational molding process. Our commitment to excellence ensures that every kiosk we manufacture is built to last, offering durability, functionality, and design flexibility. Whether you are looking for a kiosk that can withstand the elements or one that can be customized to your brand’s specifications, Inborn has the expertise and technology to deliver products that exceed your expectations.

In conclusion, rotational molding is the ideal technique for producing durable kiosks that combine strength with aesthetic appeal. Inborn’s experience and dedication to quality ensure that our kiosks offer superior performance, making them a smart investment for any application. By choosing Inborn’s rotational molded kiosks, you are selecting a product that is built to endure and designed to impress.